Your preferred supplier of used construction heavy equipment

You are here: Products»rotary drilling equipment supplier

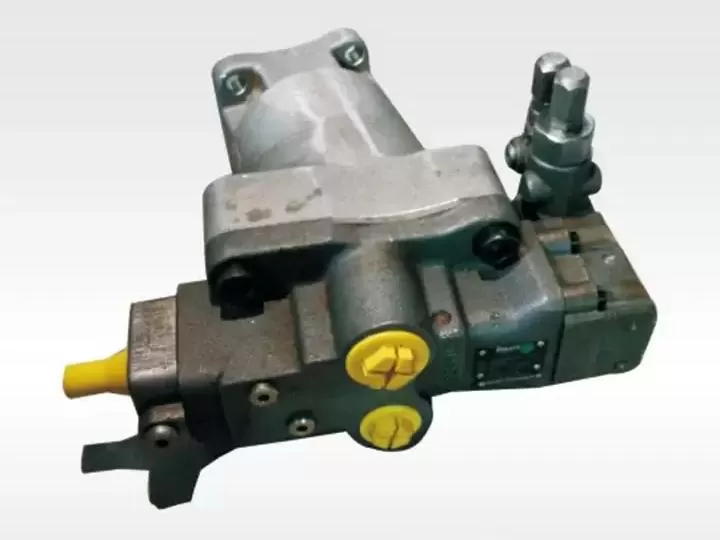

Built with advanced hydraulic systems and strong load-bearing structures, the rigs from the rotary drilling equipment supplier deliver efficient drilling even in tough geological formations. The company ensures precise control and minimal vibration for accurate depth and hole alignment. With ongoing technological upgrades, the rotary drilling equipment supplier continues to push the boundaries of construction equipment reliability and innovation.

Rotary drilling rigs from the rotary drilling equipment supplier are essential for geotechnical investigations, foundation pile installation, and urban development projects. Their high drilling capacity and stability allow them to handle complex soil and rock compositions. The rotary drilling equipment supplier ensures each rig can operate continuously while maintaining drilling accuracy and safety standards in demanding construction sites.

The rotary drilling equipment supplier envisions future rotary drilling rigs capable of integrating machine learning algorithms to optimize drilling performance. These rigs will adjust in real-time to varying geological conditions, enhancing accuracy and reducing material waste. The rotary drilling equipment supplier focuses on producing equipment that meets the demands of modern, eco-conscious construction projects.

Mining and construction sites rely on regular maintenance of rotary drilling rigs supplied by the rotary drilling equipment supplier. Essential practices include checking hydraulic pressure, inspecting drill head condition, and ensuring proper alignment of rotating components. The rotary drilling equipment supplier prioritizes preventive upkeep to reduce downtime and maintain high drilling accuracy.

The rotary drilling equipment supplier manufactures rotary drilling rigs known for their high torque, deep drilling capacity, and structural strength. Suitable for urban and industrial construction, these rigs deliver accurate drilling results in various ground conditions. The rotary drilling equipment supplier emphasizes quality manufacturing to ensure long-lasting reliability and performance.

Q: What maintenance checks are recommended for rigs from a rotary drilling rig supplier? A: Regular inspection of hydraulic systems, drill bits, engine components, and mast alignment ensures long-term reliability. Q: How do rigs from a rotary drilling rig supplier improve drilling precision? A: Intelligent control systems and real-time monitoring maintain accurate depth and vertical alignment throughout operations. Q: What types of projects benefit most from rigs supplied by a rotary drilling rig supplier? A: Foundation construction, bridge piling, urban high-rise development, and industrial facility installation. Q: How do rigs from a rotary drilling rig supplier handle hard rock formations? A: They are equipped with high-power rotary drives, reinforced drill rods, and advanced torque management for effective penetration. Q: What technological innovations are incorporated in rigs from a rotary drilling rig supplier? A: Advanced hydraulic control, automated depth monitoring, and operator-friendly interfaces enhance efficiency and safety.

Quick delivery and excellent performance. The crane handles heavy loads easily.

Smooth operation and reliable quality. The road roller is a solid investment.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Please send details on your asphalt pavers, including fuel efficiency and pricing. Are operator manu...

Please send me a quote for a mining dump truck with details on capacity.